VERISHIELD SUSTAINABLE RADIATION SHIELDING

Veritas’s VeriShield® modular radiation shielding provides several eco-friendly advantages over traditional construction methods and poured concrete solutions. Here’s what makes it a better choice:

-

Resource Efficiency: VeriShield radiation shielding modules maximize material efficiency by being manufactured in a controlled factory environment. This process reduces waste and saves water while using recycled byproducts from other manufacturers. By reusing these materials, the system prevents unnecessary landfill contributions and promotes sustainable practices.

-

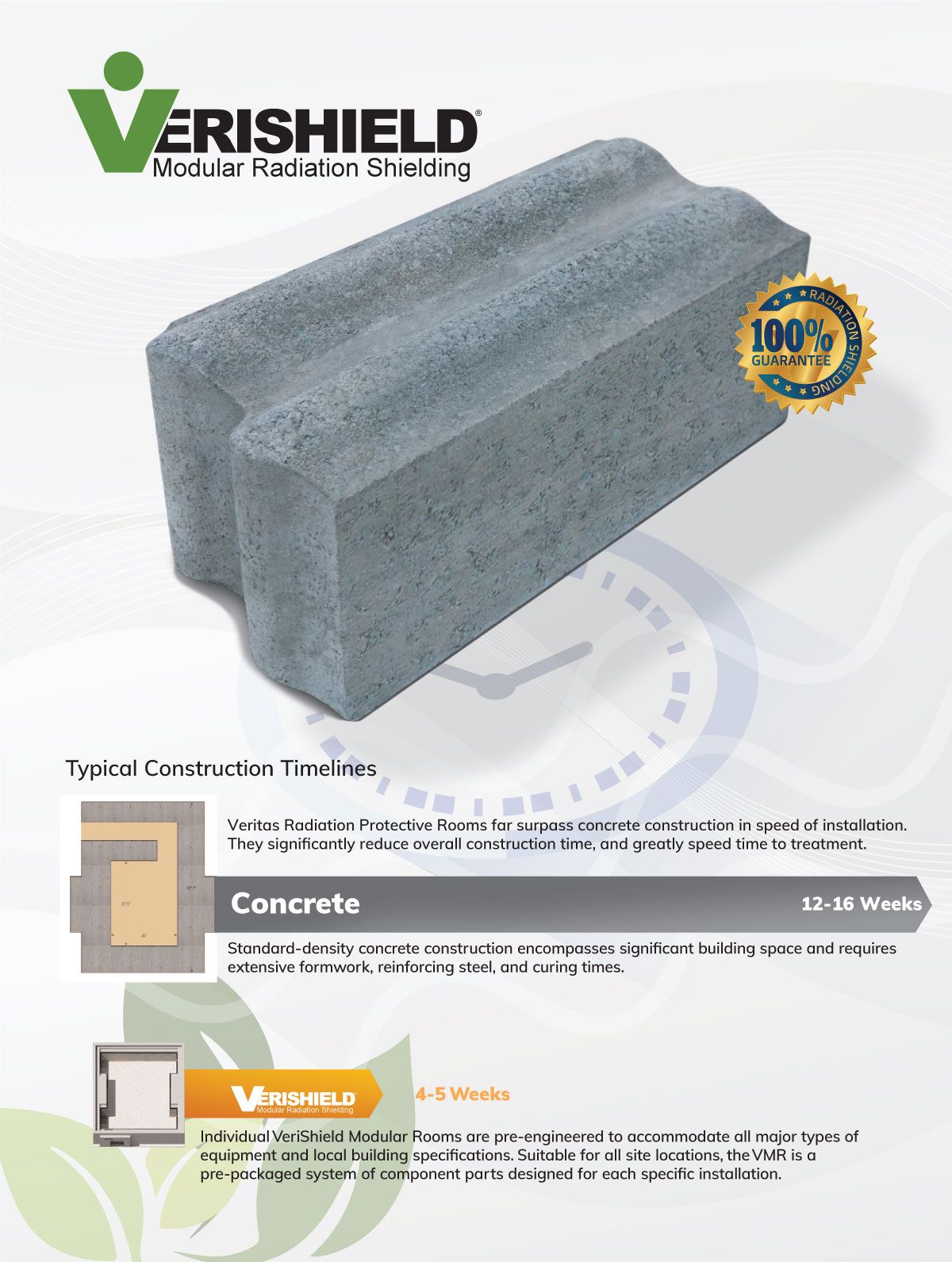

Reduced Construction Time: The ability to manufacture VeriShield modules during site preparation accelerates construction timelines. What’s more, this efficiency not only reduces energy use but also cuts down on material consumption and shipping impacts. Furthermore, minimizing construction time helps limit environmental disruption, making the process more sustainable.

-

Reuse and Repurposing: VeriShield components are designed for flexibility, allowing for easy disassembly and reuse. Also, this adaptability works well for projects involving relocation or decommissioning. By reusing these materials, the need for new resources is lowered, and the lifespan of the components is extended.

-

Space Saved Equals Fewer Materials: Compact design helps VeriShield save space, which directly reduces the need for extra building materials. For example, fewer resources like drywall, ductwork, and ceiling tiles are needed. This reduction simplifies construction while conserving materials and cutting costs.

-

Minimized Site Disturbance: Using VeriShield requires less on-site labor and fewer heavy machines compared to traditional methods. As a result, the construction process causes minimal soil erosion, reduces habitat disruption, and lowers the overall environmental impact. These benefits make it a more eco-friendly option.

-

Scalability and Flexibility: Expanding or modifying VeriShield modules is straightforward, allowing projects to adapt to changing needs. In addition, this scalability avoids the need for new construction, which helps conserve materials and reduces the environmental footprint.

-

Quality Control: Producing VeriShield modules in a factory ensures consistent quality and reliability. Over and above that, precise manufacturing leads to durable components that require fewer repairs or replacements over time. This focus on quality results in long-lasting performance and greater customer satisfaction.