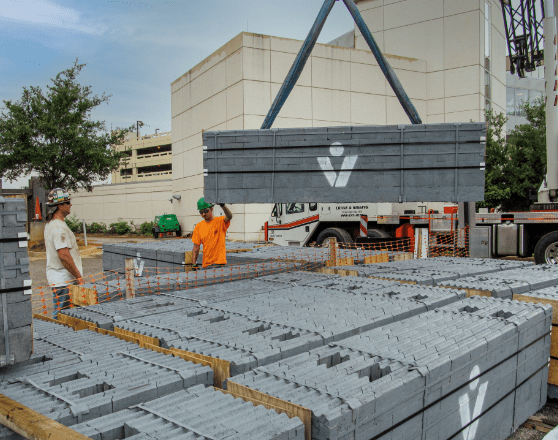

Slash Timelines with Speedy Installation of Stackable Modules using VPAC® Stackable Radiation Shielding

Construct a fully shielded room within a week. Speed up installation. Simplify logistics. Cut months from project timelines. It’s all possible with the Veritas VPAC® Stackable Radiation Shielding system, which combines individual VeriShield modules into a single structural element that interlocks with other VPAC units to form a solid homogeneous shielding structure. A proven alternative to concrete radiation shielding, installations take less than a week!

Just-In-Time Delivery with No Curing Time

Simplify installation with just-in-time delivery of VPAC units. Pre-assembled units are delivered to the site and can be installed immediately upon arrival. No manual module handling or curing time is needed. Shielded rooms are constructed in days instead of weeks, so you’re ready immediately for the next stage of construction.

Removable Modules

The VPAC system accommodates alterations, removal or adjustments to individual VeriShield modules. For future site or facility upgrades, VPAC units can be recovered and reused, or reconfigured to accommodate changes.

Consistency, Consistency, Consistency

Veritas guarantees consistent density throughout each VPAC unit. Factory fabrication eliminates density variations that create radiation hot spots in competitive constructions. VPAC units retain all of the properties of VeriShield modular shielding, including:

- Unique sine-wave curves that prevent radiation streaming through joints

- Interlocking units that dry-stack together, forming a solid integral structural element

- Guaranteed 100% radiation attenuation through factory Q.C. and in-house physics analysis

Ultra-High Densities for Thinner Barriers

VPAC units are available in a variety of sizes and thicknesses and can incorporate various densities of VeriShield modules based on physics requirements. The result? Required attenuation is provided without the overwhelming thickness of concrete.